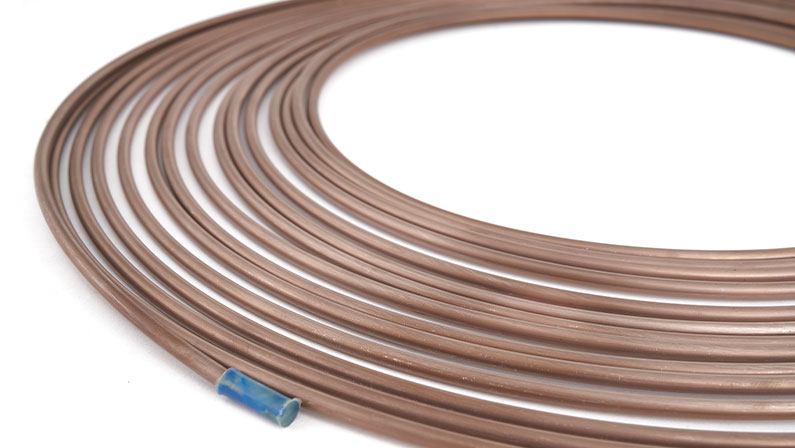

You need new brake lines for your vehicle but choosing the best type can feel overwhelming thanks to the numerous options available. Not only do you have traditional steel brake lines, but also stainless steel, PVF-coated, and nickel-copper. Like any other material, nickel-copper brake lines have their pros and cons to consider, as highlighted below.

Resists Rust and Corrosion

If you live in the rust belt of the U.S. or live close to the ocean, then you know how quickly unprotected steel can succumb to rust. Brake lines are especially vulnerable by virtue of their location underneath the vehicle and constant exposure to moisture, grime, snow, and road salt. It doesn’t take long for traditional steel brake lines to rust out and cause leaks that jeopardize the rest of the brake system, not to mention vehicle safety.

Zinc and PVF coatings offer moderate protection against rust, but total protection requires an entirely different material. While steel lacks inherent rust and corrosion resistance, brake lines made from nickel-copper alloy offer that protection in spades. Made from a mix of around 90-percent copper and 10-percent nickel for added strength, nickel-copper brake lines are practically impervious to rust and highly resistant against corrosion.

Nickel-copper brake lines aren’t just a sensible rust-free option, but also one that offers superior longevity under a variety of road conditions when compared with traditional steel brake lines.

Easy to Bend and Flare

Bending and flaring brake lines takes work, especially if you’re new to fabricating your own. Ordinary steel brake lines can be a bit troublesome to properly bend and flare. Stainless steel lines are often the most difficult to work with thanks to the hardness of the material. Having a brake line that’s easy to manipulate with basic brake line tools can help you get through any project faster.

Nickel-copper alloy is much softer than traditional steel, making it easier to manipulate than other types of brake line material. But the relative softness of nickel-copper doesn’t make it weak. The nickel part of the nickel and copper composition gives it the strength to withstand the bending you’ll do as you run your new brake line in the right spots. This makes nickel-copper a dream for novices to work with.

Costs More than Steel Brake Lines

Good materials don’t come cheap, and nickel-copper brake lines are no exception. Depending on where you buy it, you can expect to pay significantly more for brake lines made from nickel-copper alloy when compared to non-coated and zinc-coated steel lines. Nickel-copper brake lines may only run slightly higher than lines made from stainless steel, in some cases. The upside, however, is that nickel-copper brake lines last longer than their steel counterparts, meaning you won’t have to replace them as often.

Easier to Accidentally Damage

Nickel-copper brake lines are remarkably easy to bend, but they’re also easier to damage during installation. You can easily put creases or dents where you don’t want them if you’re not careful, especially if you’re using brake pliers or similar tools to make tight bends. Sealing nickel-copper brake lines also requires less torque than traditional steel lines, making it easier to crush flares with tube nuts by accident. A gentle touch comes in handy when plumbing your new nickel-copper brake lines.

Does the nickel coating burn off of lines if they become hot?

It’s a nickel-copper alloy, not a coating.

With nickel-copper brake lines dose it matter what metal compound is used for the tube nuts (steel, stainless steel, brass or aluminum)