Do you experience rhythmic thumping while driving down the road, but your brake pads are still in good shape? It may be time to have your brake rotors machined or replaced. Before you go shopping for some new parts, take some time to get a better understanding of how they bring your car to a safe stop mile after mile.

How Do Brake Rotors Work?

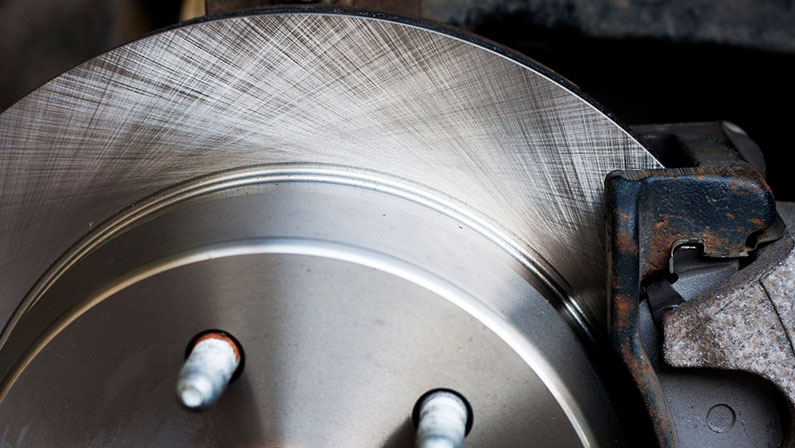

Brake rotors are bolted to the axle of the car and spin with the axle. When you hit the brake pedal, the brake calipers close and press the brake pads into contact with the rotors. Friction between the pads and rotors slows the vehicle to a controlled stop.

Rotors will wear out over time due to damage from dust and dirt thrown up from the road and degradation of the metal due to constant heating and cooling cycles.

How Often Do Brake Rotors Wear Out?

While typical brake pads in street cars wear out in about 30,000 miles, your brake rotors can last up to two to three times longer. If the surface of the brake rotor becomes scratched or warped, it is possible to have them machined to extend their functional life without replacing them immediately.

Trucks and cars that spend more time in stop-and-go traffic will wear down all the braking components faster than vehicles that spend the majority of the time on wide-open highways.

Buying Smooth, Drilled, or Slotted Brake Rotors

The majority of passenger vehicles come with OEM smooth brake rotors. Aftermarket rotors offer drilled, slotted, or drilled and slotted versions. The drilled rotor allows air, dust, and water to be dissipated faster. They are a good option if you live in an extremely wet area. Slotted rotors draw more air to the surface of the rotor, improving heat dissipation and improving performance during extreme stopping conditions.

Both slotted and drilled rotors will not last as long as your OEM smooth and will not get you a return on your investment if you are driving a commuter car or SUV. The combined drilled and slotted rotors are a popular option for street performance and off-road vehicles that are actually pushing the limits of the vehicle’s abilities.

Which is Better? Cast Iron or Steel Brake Rotors

While it may seem like cast iron is an old-school material, it still makes pretty bulletproof rotors. If you are replacing rotors on a passenger car or work truck, cast iron is affordable and dependable. Steel brake rotors are entry-level for performance rotors, as they are lighter than iron and are fairly resistant to warping. They are more expensive and will not last as long as cast iron.

Other performance material options for rotors include layered steel and ceramic. The layered steel is a nice option for cars competing at the local track. Your supercar will have a stunning set of ceramic rotors. There are some aluminum rotors on the market, which will greatly reduce weight but may not last more than a run or two down the drag strip.